Engineered Hardwood FAQ: Everything You Need to Know

Are you thinking about upgrading your home with engineered hardwood flooring? If so, odds are you want to know more about it before you invest. To help you out, we’ve compiled a list of our most frequently asked questions about engineered wood flooring so you can shop smart.

In this guide, you’ll get answers to the most common questions about engineered hardwood. Including information about its different features, how to install it, caring for and maintaining engineered wood, and how much it costs.

Let’s get started with this engineered hardwood FAQ.

In this guide, you’ll get answers to the most common questions about engineered hardwood. Including information about its different features, how to install it, caring for and maintaining engineered wood, and how much it costs.

Let’s get started with this engineered hardwood FAQ.

What is Engineered Hardwood? The Basics

Engineered hardwood is the newest alternative to solid hardwood flooring. Part wood floor, part engineering masterpiece, engineered hardwood offers the beauty of authentic hardwood with durability like no other flooring.

Topped with a real wood veneer, engineered wood planks are made with an engineered core that provides moisture resistance and durability. The plank’s construction allows engineered hardwood floor installations in any room, without worry. Be it the bathroom, kitchen, living room, or bedroom, your floors will look amazing, and hang tough against daily wear and tear.

Topped with a real wood veneer, engineered wood planks are made with an engineered core that provides moisture resistance and durability. The plank’s construction allows engineered hardwood floor installations in any room, without worry. Be it the bathroom, kitchen, living room, or bedroom, your floors will look amazing, and hang tough against daily wear and tear.

What Is Engineered Hardwood Flooring Made of?

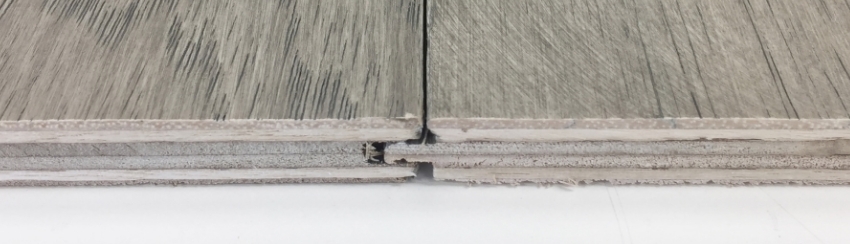

For realistic wood visuals, engineered wood is topped with a real wood veneer that’s available in a large variety of wood species, from hickory to white oak. This veneer allows real wood grain, knots, and character to shine in every plank.

Engineered wood is also made of layers consisting of either high-density fiberboard (HDF), stone-plastic composite (SPC), or an engineered plywood core layer that offers supreme durability. Some planks are even complete with an attached underlayment to provide even more comfort.

Engineered wood is also made of layers consisting of either high-density fiberboard (HDF), stone-plastic composite (SPC), or an engineered plywood core layer that offers supreme durability. Some planks are even complete with an attached underlayment to provide even more comfort.

How is Engineered Wood Made?

The process of creating engineered hardwood involves adhering the layers of the plank together. The layers for planks with an HDF core consist of the real wood veneer, a single, solid layer of HDF, and the backing layer glued together creating a sturdy flooring solution. For other cores, this process is accomplished by attaching the fiberboard plies on top of each other in opposite directions under the real wood veneer.

For that authentic hardwood look, engineered hardwood is topped with real wood veneers that are cut and created using one of three methods, each creating different characteristics in the look of the floor.

For that authentic hardwood look, engineered hardwood is topped with real wood veneers that are cut and created using one of three methods, each creating different characteristics in the look of the floor.

- Dry solid-sawn: This allows the wood to dry out slowly at a low-humidity level. While this method is more expensive, it allows the veneer to look and feel more solid.

- Rotary-peel: After boiling the log for a certain amount of time at a certain temperature, the log is then scraped along its side to create the veneer, then the veneer is pressed flat.

- Sliced-peel: This involves boiling the log for a certain amount of time at a certain temperature to prepare the wood. Then the wood is sliced from the end and pressed to create a veneer (source).

Why Should You Choose Engineered Hardwood?

Engineered wood flooring is growing in popularity because of its realistic wood looks and eco-friendliness. But there’s so much more to love about this floor than just its looks. Here are even more reasons why you should choose engineered hardwood.

- DIY-friendly: More and more engineered wood is being designed as interlocking flooring to maximize ease of installation.

- Every plank is unique: Since this is a real wood veneer, you’ll never find a repeating pattern or an unconvincing texture.

- Stylish: Wood-look flooring is the hottest trend right now, but it’s also a classic look that ages well. With engineered wood, you don’t have to settle for the look of wood. You get the real thing!

- Moisture resistance: Depending on the core of your flooring, your engineered wood could be moisture resistant or even 100% waterproof.

- Install it anywhere: High moisture resistance means you can install it in bathrooms, kitchens, laundry rooms, and even basements! No grade level of your home is off-limits.

What is the Janka Hardness Test?

The Janka hardness test is a way of testing how durable wood is. It measures the force required for a steel ball to be embedded into a sample piece of wood. This test then rates wood to determine if the sample is suitable for flooring. Ideally, the more force it takes to embed the steel ball, the more durable the wood’s surface is against impact and pressure.

Since engineered wood flooring is topped with real wood, the Janka rating scale is used to ensure excellent durability. The standard rating for all wood flooring options is a rating of 1000 pounds of force or higher.

Since engineered wood flooring is topped with real wood, the Janka rating scale is used to ensure excellent durability. The standard rating for all wood flooring options is a rating of 1000 pounds of force or higher.

What Is a Good Wear Layer for Engineered Wood Flooring?

With some engineered wood floors, the wear layer for engineered wood is a part of the real wood veneer. Therefore, the thickness of the veneer and the wood’s finish determines how long-lasting and high-quality your engineered wood floor is. It’s recommended that an engineered wood wear layer is between 3mm – 5mm thick. To ever refinish your engineered hardwood flooring, the wear layer and real wood veneer should be 3mm or thicker.

Are Engineered Hardwood Floors Durable?

Engineered wood floors are one of the more durable flooring options on the market thanks to their construction. Made of a moisture-resistant core and a sturdy hardwood veneer, engineered hardwood floors are ready to look great regardless of years of wear and tear.What’s the Difference Between Engineered Wood and Solid Hardwood?

The key difference between hardwood and engineered hardwood is the construction, installation process, and where they can be installed.

While hardwood floors are wood logs cut into planks, each engineered wood plank is topped with a thin hardwood veneer to create a hardwood surface on top of an engineered core. Engineered wood is then made up of composite materials such as a high-density fiberboard (HDF). This construction makes engineered wood more eco-friendly because the bulk of the plank is made from faster-growing materials instead of an entire plank of old-growth wood.

As for installation, engineered hardwood is much more DIY-friendly with a simple tongue and groove installation process. Not to mention it can also be installed in more areas of the house than solid hardwood floors.

While hardwood floors are wood logs cut into planks, each engineered wood plank is topped with a thin hardwood veneer to create a hardwood surface on top of an engineered core. Engineered wood is then made up of composite materials such as a high-density fiberboard (HDF). This construction makes engineered wood more eco-friendly because the bulk of the plank is made from faster-growing materials instead of an entire plank of old-growth wood.

As for installation, engineered hardwood is much more DIY-friendly with a simple tongue and groove installation process. Not to mention it can also be installed in more areas of the house than solid hardwood floors.

What’s the Difference Between Engineered Wood and Laminate?

Though they might look similar, engineered wood floors are not the same as laminate floors. While they are both durable flooring options, the main difference between the two is their construction.

Engineered wood contains a top layer of solid wood with a durable engineered core. Laminate uses a photographic layer coated with a wear layer to achieve the wood-look surface, with a core board, and a stabilizing backing layer.

Engineered wood contains a top layer of solid wood with a durable engineered core. Laminate uses a photographic layer coated with a wear layer to achieve the wood-look surface, with a core board, and a stabilizing backing layer.

Are Engineered Wood Floors Waterproof?

Thanks to its multi-layered design and sturdy core, all engineered wood resists water better than solid hardwood. However, only planks with the stone-plastic composite (SPC) core are considered 100% waterproof.

What is the Best Thickness for Engineered Wood Flooring?

The range of thickness depends on your budget and the quality of engineered wood flooring. For an engineered hardwood the most desired thickness can be anywhere from 1/2″- 5/8″ thick.

The thickness of the floor’s real wood veneer also determines how long your floors will look like new. The top layer of the floor protects the floor from wear and tear, and prolongs the livelihood of engineered wood. Therefore, it’s standard for wear layers and veneer to range from 3mm-7mm thick to ensure long-lasting flooring beauty. Remember, the thicker the wear layer and real wood veneer the better.

The thickness of the floor’s real wood veneer also determines how long your floors will look like new. The top layer of the floor protects the floor from wear and tear, and prolongs the livelihood of engineered wood. Therefore, it’s standard for wear layers and veneer to range from 3mm-7mm thick to ensure long-lasting flooring beauty. Remember, the thicker the wear layer and real wood veneer the better.

How Long Does an Engineered Wood Floor Last?

The lifespan of engineered wood flooring ranges from 20-80 years. The livelihood of the floor comes down to its surface layers, and how well you take care of your floors.

If you’re installing engineered hardwood floors with a 2mm wear layer in a high traffic area, the floors won’t last as long because you can’t refinish them without the recommended 3mm thick wear layer. Refinishing can add decades to your floor if you’re installing into a high traffic area. If the wear layer is thinner, it could last 20-30 years, whereas a plank with a thicker wear layer could have a lifespan of 40-80 years.

Remember, considering the foot traffic and environment while installing your floors will help your floors last.

If you’re installing engineered hardwood floors with a 2mm wear layer in a high traffic area, the floors won’t last as long because you can’t refinish them without the recommended 3mm thick wear layer. Refinishing can add decades to your floor if you’re installing into a high traffic area. If the wear layer is thinner, it could last 20-30 years, whereas a plank with a thicker wear layer could have a lifespan of 40-80 years.

Remember, considering the foot traffic and environment while installing your floors will help your floors last.

How to Install Engineered Hardwood

There are four methods of installing engineered hardwood flooring, all of which can be accomplished by yourself or by an installation professional.

- Floating floor: The tongue and groove method is the most common installation method for engineered hardwood. Insert the tongue of one plank into the groove of another to attach the planks. To float tongue and groove planks, you will need to glue the planks together using tongue and groove glue unless the planks have an interlocking system.

- Nail-down: You need to have a wood subfloor for this method. Using a power nailer, apply fasteners into the tongue of the planks, and then lock the next row of planks together before also fastening them down as well. If you’re comfortable using power tools, then you might be able to install them yourself.

- Staple-down: If you want to use staples to fasten your engineered hardwood to the subfloor, then you’ll use the same techniques as nail-down installation.

- Glue-down: You can glue down engineered hardwood when you want to make sure it stays secure, such as when you’re installing flooring in a high traffic area. Glue-down installation is a permanent solution, and while it can be done on your own it’s also pretty tricky, so this method is best left to the pros.

What’s the Best Way to Install Engineered Hardwood?

Using one of the four installation methods, such as floating the floor, gluing the planks down, or nailing or stapling them down you can have a new gorgeous floor in no time.

What makes one method the “best” depends on your comfort with different tools and where you’re installing it. For instance, a floating floor installation requires no power tools and is recommended for low-traffic, residential areas. Whereas the nail-down installation method uses a nail gun and is best suited for commercial installations.

What makes one method the “best” depends on your comfort with different tools and where you’re installing it. For instance, a floating floor installation requires no power tools and is recommended for low-traffic, residential areas. Whereas the nail-down installation method uses a nail gun and is best suited for commercial installations.

Can I Install Engineered Hardwood Myself?

The easiest way to install engineered hardwood is the floating floor method, and you can do this yourself. This is the process of locking the planks together over the subfloor using its tongue and groove. This method does not require the use of power tools but might require tongue and groove adhesive to secure the planks if they don’t lock together. Other installation methods include nail-down, staple-down, and glue-down.

While the floating floor method is more catered to a DIY flooring project, glue-down, nail-down, and staple-down methods do not require a professional. It all depends on your comfort with flooring adhesives and power tools. Just be sure to contact your flooring manufacturer for complete installation instructions.

While the floating floor method is more catered to a DIY flooring project, glue-down, nail-down, and staple-down methods do not require a professional. It all depends on your comfort with flooring adhesives and power tools. Just be sure to contact your flooring manufacturer for complete installation instructions.

Should Engineered Wood Acclimate Before Installation? Why?

Regardless of the type of engineered wood floors you choose, it must acclimate to its new environment for at least 24 hours to adjust to the temperature and humidity of the area. While engineered hardwood does not expand and contract as much as hardwood, acclimation ensures proper installation and durability.

The process of acclimation helps planks adjust to the temperature of the room before installation. Some flooring can expand and contract in humid areas, causing your floor to buckle or squeak. This is why most flooring should acclimate to its surroundings for at least 24 hours to prevent any post-installation issues.

The process of acclimation helps planks adjust to the temperature of the room before installation. Some flooring can expand and contract in humid areas, causing your floor to buckle or squeak. This is why most flooring should acclimate to its surroundings for at least 24 hours to prevent any post-installation issues.

Where Can Engineered Hardwood be Installed?

Because of its moisture resistance, engineered hardwood can be installed in kitchens, laundry rooms, and even basements.Thanks to its excellent durability, engineered wood is strong enough to be installed in both residential and commercial settings, so your business and your home will look great. Plus, it can be installed over most subfloors, and there’s no grade level of your home that’s off-limits. Some planks are complete with an attached underlayment, making them ready for anything in every room of the house.

Does Engineered Hardwood Require Underlayment?

Regardless of its durable construction, engineered wood almost always requires an underlayment. Because it stops moisture build-up under your floors, keeps your floors warm, reduces noise, and evens out subfloor imperfections, underlayment is an important part of installing engineered wood flooring. This extra support will lengthen the life of your engineered wood floors.

For even more convenience, some engineered hardwood flooring comes with attached underlayment.

For even more convenience, some engineered hardwood flooring comes with attached underlayment.

What is the Best Underlayment for Engineered Hardwood Floors?

There’s no one “best” underlayment for engineered wood. The engineered hardwood underlayment options depend on where you’re installing the floor, and what your goals are. If you’re worried about subfloor moisture damaging your floor, an underlayment with an attached vapor barrier is recommended. Whereas if you’re more concerned about sound control and acoustics, a foam or cork underlayment under engineered hardwood will do the trick.

Remember to prioritize your flooring goals when choosing a proper underlayment for engineered hardwood.

Remember to prioritize your flooring goals when choosing a proper underlayment for engineered hardwood.

Can You Lay Engineered Hardwood Over Hardwood?

The awesome thing about engineered hardwood is it can be floated over most surfaces with the right underlayment. Therefore, engineered wood floors can be installed over laminate, vinyl, and solid hardwood floors, among other surfaces. However, other installation options such as glue-down or nail-down are not recommended when installing over existing floors.

How to Clean and Care for Engineered Hardwood

Once your beautiful engineered flooring is installed, you’ll need to know how to properly clean and care for your floors. Let’s see if these answers will help you along the way.

How Do You Clean Engineered Hardwood Floors?

Simply, very common cleaning practices help keep engineered wood floors clean. To ensure a long-lasting, gorgeous floor, practice this cleaning routine regularly.

- Sweep often: Getting that excess dirt off your floors keeps your engineered wood floors looking gorgeous. Dirt, if not removed, gets ground into your floors and can cause damage over time. If you are using a vacuum, be sure it is set to the bare floor setting, because a beater bar can scratch or dent your floor.

- Use a damp mop: When mopping engineered wood, it’s best to use a damp – but not wet – mop. Too much moisture will sit on your floors and seep through the planks, which could cause subfloor damage or warping. So, when you dunk your mop into the cleaning solution, be sure to wring it out thoroughly so it is damp to the touch. Mopping your engineered hardwood floor does not have to be intense. Just be sure your floors get cleaned regularly.

Can I Use a Swiffer on Engineered Hardwood?

Swiffer mops are an appropriate tool for sweeping and damp-mopping your engineered hardwood. Products like Swiffer dry and wet refills are also great alternatives to pick up any loose dirt or handle those tough stuck-on spots. The Swiffer Wet-Jet in particular is one of the best tools for cleaning engineered hardwood.

Can I Use a Steam Mop on Engineered Wood?

When caring for engineered wood floors, steam cleaning is not recommended. Steam mopping uses hot water, which causes engineered wood planks to warp and allows moisture to seep through the floor, compromising the subfloor and the construction of the planks. Unless you want to replace your flooring every few years, steam cleaning is not a proper cleaning method for engineered wood floors.

How Do You Clean Engineered Wood Floors Without Streaks?

Believe it or not, a common cause for streaks and residue on engineered wood is simply not thoroughly rinsing and cleaning your mop or mop pad regularly. You can use clean water and solution every time, but if your mop is dirty it will leave residue behind on your engineered wood floors. Make sure you are properly rinsing and wringing out your mop while cleaning and after you’re done.

Something else that causes streaks is your cleaning solution. Finding products that are non-streak will make cleaning your floors much easier. Products like Bona or Simple Green Multi-Surface Floor Care are known for their non-streaking results.

Something else that causes streaks is your cleaning solution. Finding products that are non-streak will make cleaning your floors much easier. Products like Bona or Simple Green Multi-Surface Floor Care are known for their non-streaking results.

How Often Should Engineered Hardwood be Cleaned?

The frequency of cleaning your engineered wood floors depends on the amount of foot traffic your floors see. Ideally, in low-foot traffic areas of the home, basic cleaning happens twice weekly. For busier homes with pets, kids, or just a lot of people, daily sweeping and light mopping is key to keeping your floors in shape.

What is the Best Cleaner for Engineered Wood Floors?

It’s always best to reach out to your floor manufacturer to determine the best cleaner for their product. But if you don’t have that information on hand it’s recommended to use a wood floor cleaner on engineered wood floors. Cleaners for other types of flooring like vinyl can be harmful to engineered wood since it is topped with a real wood veneer.

Store-bought wood floor cleaners such as Bona or Simple Green Multi-Surface Floor Care work great for engineered wood. But if store-bought cleaning solutions aren’t for you, you can create a cleaner with household ingredients like warm water, white vinegar, essential oils, or lemon juice.

For basic cleaning, combine these ingredients.

Store-bought wood floor cleaners such as Bona or Simple Green Multi-Surface Floor Care work great for engineered wood. But if store-bought cleaning solutions aren’t for you, you can create a cleaner with household ingredients like warm water, white vinegar, essential oils, or lemon juice.

For basic cleaning, combine these ingredients.

- 1 gallon of warm water

- 1/4 cup white vinegar

- (optional) 5-10 drops of essential oil or lemon juice

- 1 gallon of warm water

- 3/4 cup olive oil

- 1/2 cup lemon juice

Can Engineered Wood Floors Get Scratched?

Just like traditional wood floors, engineered hardwood can get scratched. But it can also be easily disguised or repaired.

Instead of refinishing your entire floor as you would with solid hardwood, you can repair scratches on engineered hardwood with concealing methods. You can mask the scratch with a concealer that matches your floor, use a floor-matching felt tip craft marker to disguise scratches, or use a floor repair wax kit that matches your floor.

Instead of refinishing your entire floor as you would with solid hardwood, you can repair scratches on engineered hardwood with concealing methods. You can mask the scratch with a concealer that matches your floor, use a floor-matching felt tip craft marker to disguise scratches, or use a floor repair wax kit that matches your floor.

Can You Refinish Engineered Wood Floors?

Engineered wood should not be refinished unless specified by the flooring manufacturer.

If your engineered floors can be refinished, check to make sure the floors have at least a 3mm wear layer and have been installed for several years. Engineered hardwood should only need to be refinished after years of wear. If the wear layer is less than 3mm, the real wood veneer could be too thin and cause damage to your engineered wood planks. Remember, it’s always best to check with the flooring manufacturer to better understand the correct process for refinishing their floors.

If your engineered floors can be refinished, check to make sure the floors have at least a 3mm wear layer and have been installed for several years. Engineered hardwood should only need to be refinished after years of wear. If the wear layer is less than 3mm, the real wood veneer could be too thin and cause damage to your engineered wood planks. Remember, it’s always best to check with the flooring manufacturer to better understand the correct process for refinishing their floors.

Does Engineered Hardwood Need to be Sealed?

Most engineered hardwood often comes pre-finished and does not need to be sealed. However, if you would like to add an extra layer of protection from water leaks and spills, you can add a seal to engineered wood. Sealing your floor will keep the floors intact for longer.

Remember to always check with your flooring manufacturer to better understand the sealing process, and to make sure it’s recommended for your kind of engineered hardwood flooring.

Remember to always check with your flooring manufacturer to better understand the sealing process, and to make sure it’s recommended for your kind of engineered hardwood flooring.

How Do You Cut Engineered Hardwood?

Learning how to cut engineered wood planks is an important part of the installation process. Thankfully, with the right tools, it’s a simple process. Check it out.

- Some floors and their wear layer can create excess dust when cutting the planks. For safety, be sure to wear a mask when cutting the planks.

- Mark the top side of the plank where it should be cut using chalk or a pencil.

- Using a table saw, miter saw, circular saw, or hand saw, cut the plank with the finished side up.

Costs of Engineered Hardwood

Ready to start talking numbers? Let’s talk about the costs that come with engineered hardwood.

How Much Does Engineered Hardwood Cost?

Engineered wood prices vary and depend on the thickness of the real wood veneer, and the core’s material and layering process. On average, engineered wood flooring costs $4 – $7 per sqft but also could be more or less depending on the flooring brand. According to HomeAdvisor, higher quality engineered wood floors range from $8 – $12 per sqft.

How Much Does it Cost to Install Engineered Hardwood?

The labor cost to install engineered hardwood floors averages between $3 to $8 per square foot for professional installation. However, to save money on your project, some engineered wood floors are made to lock together using tongue and groove planks which can be installed by you much faster than hiring a professional (source).

Does Engineered Hardwood Help the Resale Value of a House?

Engineered hardwood can increase the value of your home the same amount as solid hardwood. You’ll recoup 70% to 80% of your investment through your property values with engineered wood because of its style and durability. Not only does it cost less to install than solid hardwood, but also, with engineered wood, you get the realistic look of hardwood with more moisture resistance.

Conclusion

Viola! Now you know everything you need to know about engineered hardwood floors. Now you can shop smart and find what dreams are made of with engineered hardwood.